In the realm of modern healthcare, certain technologies are critical, though often unrecognized, in ensuring the effective delivery of patient care. One such vital technology is the medical air compressor. Essential to the functioning of hospitals, clinics, and other healthcare facilities, medical air compressors provide the clean, dry, and compressed air required for a variety of medical applications. From ventilators in critical care units to anesthesia delivery in operating rooms, medical air compressors are the unseen backbone of several medical systems.

This article will explore the anatomy, function, applications, and significance of medical air compressors, along with the regulations and innovations that drive their usage in healthcare settings.

1. The Basics of a Medical Air Compressor

What is a medical air compressor?

A medical air compressor is a mechanical device used in healthcare settings to supply compressed air for medical applications. Unlike industrial air compressors, medical air compressors are designed to produce air that meets strict purity, dryness, and cleanliness standards, making them safe for direct patient use.

The primary role of a medical air compressor is to generate medical-grade compressed air, which is required for various medical devices, treatments, and procedures. This air is typically free from contaminants, moisture, and oil, and must adhere to specific pressure and flow requirements, depending on the intended use.

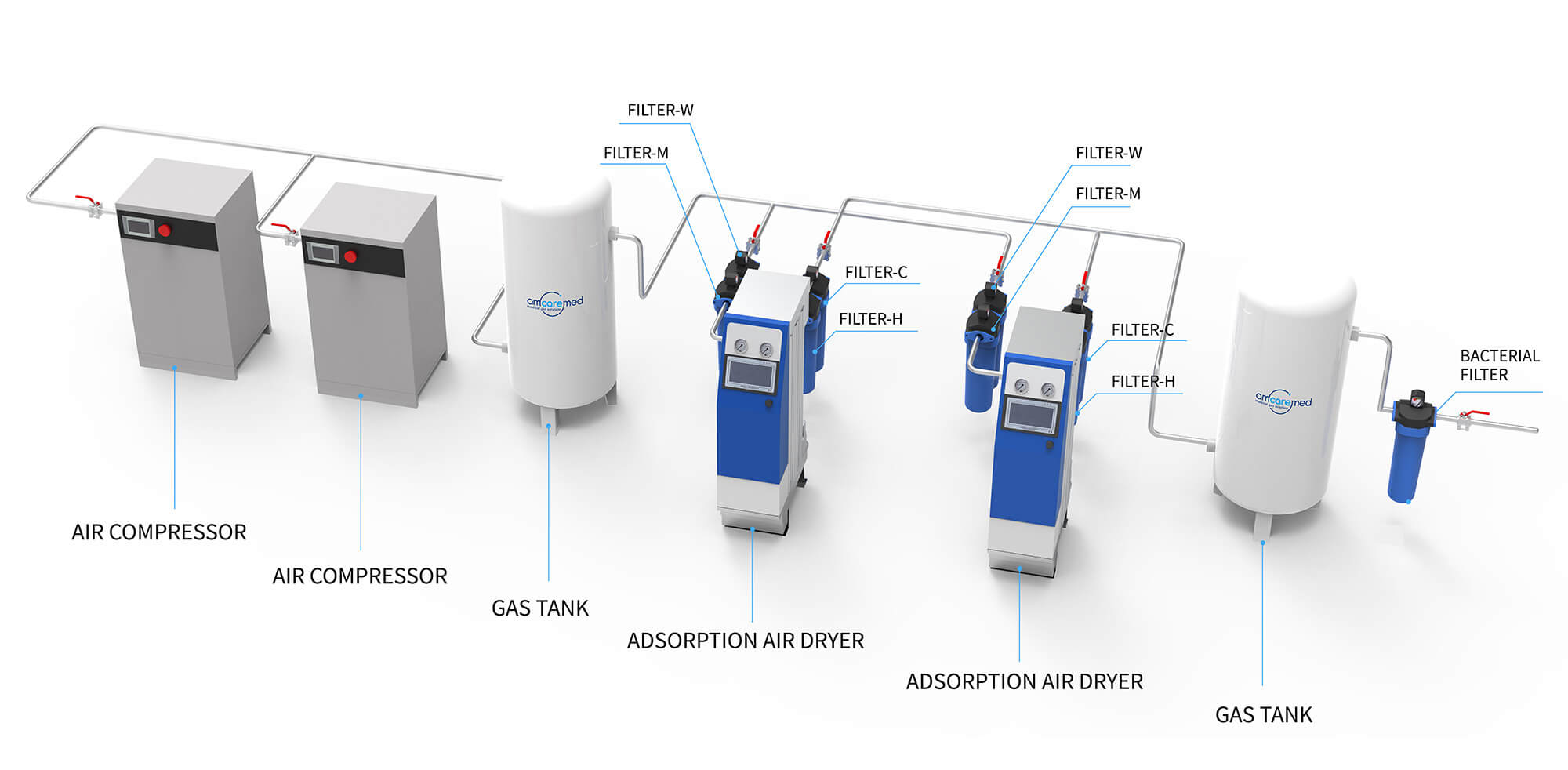

2. Components of a Medical Air Compressor

Medical air compressors are composed of several critical components, each serving a specific function to ensure the continuous supply of high-quality air:

- Compressor Unit: The heart of the system, the compressor unit, is responsible for compressing ambient air to the required pressure. Medical air compressors are available in various types, such as piston compressors, rotary screw compressors, and scroll compressors. Each type offers unique advantages based on the application.

- Air Intake Filter: The air intake filter ensures that only clean air enters the compressor by removing dust, debris, and other particulates. This step is critical in maintaining the purity of the medical air.

- Moisture Separator and Dryer: Compressed air often contains moisture, which must be removed before it is safe for medical use. Moisture separators and dryers eliminate water vapor, preventing condensation in medical equipment and the delivery of moist air to patients.

- Pressure Regulator: Medical applications require air at a precise pressure, which is managed by the pressure regulator. This component ensures that the air supplied meets the exact pressure requirements for different medical devices.

- Filters: After compression, the air is passed through a series of filters to remove any remaining contaminants, including dust, oil, and bacteria. These filters are essential for ensuring the air is safe for patient use.

- Storage Tank: The compressed air is often stored in a tank to ensure a constant supply. The tank also helps in managing fluctuations in demand, providing a buffer when the air supply needs to increase rapidly.

- Monitoring and Control Systems: Modern medical air compressors are equipped with control systems that monitor pressure, flow, temperature, and purity. These systems alert operators to any issues, such as a drop in pressure or contamination in the air supply, ensuring continuous and safe operation.

3. Types of Medical Air Compressors

Medical air compressors come in various types, each tailored to specific healthcare needs. Below are the most common types:

Piston compressors are one of the oldest and most reliable types of air compressors. They operate using pistons driven by a crankshaft, compressing air in a chamber before storing it in a tank. These compressors are known for their durability and high-pressure capabilities, making them suitable for demanding medical applications, such as operating room ventilation and anesthesia systems.

However, piston compressors tend to produce more noise and require regular maintenance due to wear on the pistons and seals.

Rotary screw compressors use two helical screws to compress air. These compressors are known for their efficiency, continuous operation, and relatively quiet performance. Because they can deliver a constant flow of air without the need for a storage tank, rotary screw compressors are often used in applications requiring a steady air supply, such as respiratory therapy or intensive care ventilation.

Scroll compressors are compact, quiet, and efficient, making them ideal for smaller healthcare facilities or specific applications that require low to moderate air pressure. Scroll compressors use two interlocking spiral-shaped scrolls, with one fixed and the other rotating, to compress air. Their compact design and minimal moving parts result in lower maintenance costs and quieter operation compared to piston compressors.

4. Key Applications of Medical Air Compressors

Medical air compressors are integral to the operation of various medical systems and devices. Here are some of the most common applications:

- Ventilation and Respiratory Support

In intensive care units (ICUs) and emergency rooms, medical air compressors provide the air needed for ventilators, which assist patients with breathing. Ventilators blend compressed medical air with oxygen to deliver a precise mixture of gases to the patient’s lungs. This application is critical in treating patients with respiratory failure, chronic obstructive pulmonary disease (COPD), or those undergoing surgery.

- Anesthesia Delivery

Anesthesia machines used in operating rooms rely on medical air compressors to deliver a precise mixture of anesthetic gases and oxygen. The compressor provides the air pressure needed to ensure the safe and controlled delivery of anesthesia during surgical procedures. Any fluctuations in air pressure could compromise the patient’s safety, making the reliability of the medical air compressor paramount.

- Nebulizers and Oxygen Therapy

For patients with respiratory conditions such as asthma, bronchitis, or pneumonia, nebulizers and oxygen therapy devices use compressed air to deliver medication in the form of a fine mist, allowing it to be easily inhaled into the lungs. Medical air compressors ensure the air pressure required for nebulization is maintained, enhancing the effectiveness of treatment.

- Surgical Tools

Many surgical tools, such as pneumatic drills, saws, and other powered instruments, rely on compressed air for their operation. These tools are commonly used in orthopedic, dental, and ophthalmic surgeries. A medical air compressor provides the compressed air needed to power these tools, ensuring precise control and reliability during surgical procedures.

- Air Supply for Hyperbaric Chambers

In hyperbaric oxygen therapy, patients are placed in a pressurized chamber filled with pure oxygen or a mixture of oxygen and compressed air. Medical air compressors play a critical role in regulating the pressure within the chamber, ensuring that patients receive the correct oxygen dosage under the appropriate pressure conditions.

5. Regulatory Standards and Guidelines for Medical Air Compressors

Medical air compressors must adhere to stringent standards to ensure they produce safe, high-quality air suitable for medical use. Several international standards and guidelines govern the design, installation, and maintenance of medical air compressors. Some of the key regulations include:

- ISO 7396-1: Medical Gas Pipeline Systems

This international standard specifies requirements for the design, installation, commissioning, and validation of medical gas pipeline systems, including medical air compressors. It outlines the minimum standards for air purity, pressure control, and filtration, ensuring that the air supplied to patients is safe and free from contaminants.

- NFPA 99: Health Care Facilities Code

In the United States, the National Fire Protection Association (NFPA) publishes the NFPA 99 Health Care Facilities Code, which sets forth safety guidelines for healthcare systems, including medical gas systems. The code covers medical air compressor requirements such as redundancy, maintenance, and testing to ensure patient safety in healthcare facilities.

- European Pharmacopoeia Standards

The European Pharmacopoeia sets strict guidelines for the quality of medical air used in healthcare settings. Medical air is classified as a medicinal product, and its production must meet purity specifications, including limits on contaminants such as carbon monoxide, oil, and particles.

6. Maintenance and Safety Considerations

Like any critical healthcare equipment, medical air compressors require regular maintenance to ensure their continued reliability and safety. Proper maintenance reduces the risk of system failure, contamination, or pressure inconsistencies, all of which could compromise patient safety.

- Regular Inspection and Testing

Routine inspections are necessary to check for wear and tear, leaks, or any signs of damage to the compressor components. Testing of pressure levels, air quality, and flow rates should be performed regularly to ensure the compressor is functioning within the required parameters.

- Filter Replacement

Filters in medical air compressors play a vital role in removing contaminants such as dust, oil, and bacteria from the compressed air. Over time, these filters become clogged and lose efficiency, requiring regular replacement to maintain air purity.

- Moisture Management

Moisture separators and dryers are crucial in preventing condensation in the compressed air. If moisture accumulates in the air lines or medical equipment, it can lead to bacterial growth, corrosion, and compromised air quality. Regular maintenance of moisture management systems is essential to ensure safe and dry air delivery.

- Redundancy and Backup Systems

To prevent interruptions in air supply, many healthcare facilities install redundant medical air compressors or backup systems. This ensures that, in the event of a compressor failure, a backup unit can immediately take over, maintaining a continuous supply of compressed air.

7. Innovations and Future Trends in Medical Air Compressors

As technology advances, medical air compressors continue to evolve with innovations aimed at improving efficiency, safety, and environmental sustainability. Some of the emerging trends in medical air compressor technology include:

- Energy Efficiency

With a growing emphasis on sustainability, manufacturers are developing energy-efficient medical air compressors that reduce power consumption without compromising performance. Variable-speed compressors, which adjust their output based on demand, are becoming more common in healthcare facilities, lowering energy costs and reducing environmental impact.

- Smart Monitoring Systems

Many modern medical air compressors now come equipped with smart monitoring systems that provide real-time data on air pressure, flow, temperature, and purity. These systems can send alerts in the event of a malfunction, enabling proactive maintenance and reducing the risk of unexpected failures.

- Oil-Free Compressors

To further enhance air purity and reduce the risk of contamination, oil-free medical air compressors are gaining popularity. These compressors use advanced materials and design techniques to eliminate the need for lubricating oil, making them safer and easier to maintain in healthcare environments.

8. Conclusion

Medical air compressors are the lifeline of modern healthcare, providing the clean, compressed air required for a wide range of critical medical applications. From respiratory support and anesthesia delivery to powering surgical tools and hyperbaric chambers, these devices ensure that healthcare professionals can deliver safe and effective patient care.

As technology continues to advance, medical air compressors are becoming more efficient, reliable, and sustainable, playing an ever-increasing role in the future of healthcare. Whether in large hospitals or small clinics, the importance of medical air compressors cannot be overstated – they are truly an essential component of the healthcare infrastructure.