1. Introduction

Oxygen is an essential element for life, and its demand has surged, particularly during the COVID-19 pandemic. Pressure Swing Adsorption (PSA) oxygen plants have played a crucial role in meeting this demand by generating oxygen on-site. At the heart of these plants are compressors, vital for the efficient functioning of the PSA process. In this article, we delve into the types of air compressors commonly used in PSA oxygen plants and their significance in ensuring a reliable oxygen supply.

2. Understanding PSA Oxygen Plants

PSA oxygen plants utilize the principle of adsorption to separate oxygen from the surrounding air. Ambient air contains approximately 21% oxygen and 78% nitrogen, with trace amounts of other gases. The PSA process involves passing compressed air through a bed of adsorbent material, typically molecular sieves, where nitrogen is selectively adsorbed, allowing the remaining oxygen to be collected as a high-purity gas stream.

3. Air Compressor’s Role in PSA Oxygen Plants

Compressors are an integral component of PSA oxygen plants, responsible for supplying compressed air to the adsorption beds. The compressed air serves as the feedstock for the PSA process, undergoing separation to produce oxygen-rich gas. The efficiency and reliability of the compressor directly impact the overall performance and output of the oxygen plant.

4. Types of Air Compressors Used

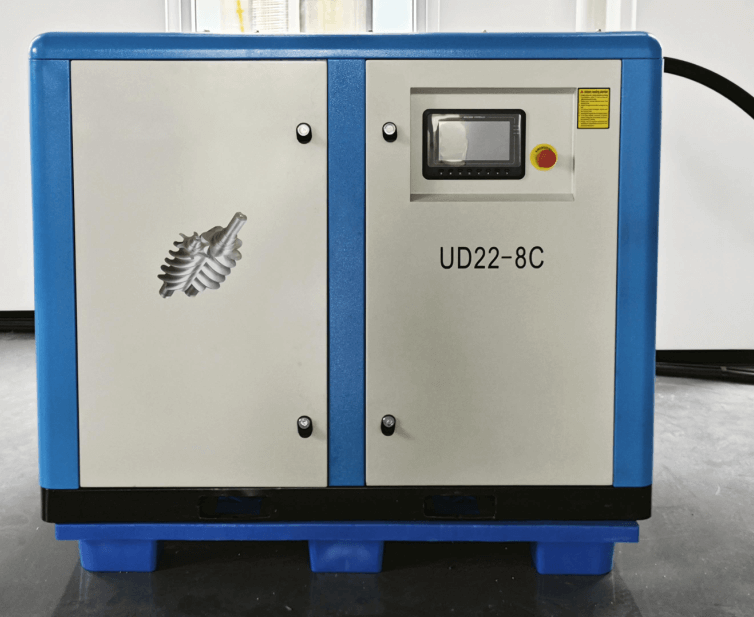

4.1 Rotary Screw Compressors

Rotary screw air compressors are widely employed in PSA oxygen plants due to their robustness, efficiency, and ability to deliver a continuous supply of compressed air. These compressors feature two interlocking helical rotors that compress air as they rotate. They offer high reliability, minimal pulsation, and are relatively low maintenance compared to other types of compressors.

4.2 Reciprocating Compressors

Reciprocating air compressors utilize pistons driven by a crankshaft to compress air. While less common in PSA oxygen plants compared to rotary screw compressors, reciprocating compressors are still used in smaller-scale installations or where specific operational requirements dictate their use. They provide excellent compression efficiency and can handle varying load demands effectively.

4.3 Scroll Compressors

Scroll air compressors are characterized by two interleaving spiral-shaped scrolls, one stationary and the other orbiting, to compress air. Although less prevalent in PSA oxygen plants, scroll compressors are valued for their compact size, quiet operation, and minimal maintenance needs. They are often utilized in smaller-scale or portable oxygen generation systems.

5. Factors Influencing Compressor Selection

The choice of compressor type for a PSA oxygen plant depends on various factors, including plant capacity, operating conditions, space constraints, energy efficiency requirements, and budget considerations. Larger-scale installations typically favor rotary screw compressors for their reliability and high flow rates, while smaller systems may opt for reciprocating or scroll compressors to optimize space and energy usage.

6. Conclusion

Compressors play a critical role in the operation of PSA oxygen plants, facilitating the efficient generation of oxygen from ambient air. Rotary screws, reciprocating, and scroll compressors are the primary types utilized, each offering distinct advantages in terms of performance, reliability, and suitability for different plant configurations. By selecting the appropriate compressor type and ensuring proper maintenance, PSA oxygen plant operators can ensure a steady supply of high-quality oxygen to meet the growing demand for medical, industrial, and other applications.

If you have more questions about air compressors or oxygen plants, please contact Amcaremed, we are always ready to provide services for you.