In the ever-evolving landscape of modern medicine, technological advancements continually revolutionize surgical procedures, aiming to enhance patient outcomes, improve safety, and streamline workflows. One significant innovation in surgical infrastructure is the advent of modular operating theaters. These cutting-edge facilities represent a fusion of engineering ingenuity and medical expertise, offering unprecedented flexibility, efficiency, and customization in the surgical environment. In this article, we embark on a journey to unravel the intricacies of modular operating theaters and understand their profound impact on the future of surgery.

1. The Genesis of Modular Operating Theaters

Traditionally, operating theaters were constructed as permanent fixtures within hospital buildings, with fixed layouts and infrastructure. However, as healthcare systems grapple with the challenges of cost-effectiveness, scalability, and adaptability, the concept of modular operating theaters emerged as a revolutionary solution. Inspired by modular construction techniques seen in architecture and engineering, modular operating theaters leverage prefabricated components, standardized interfaces, and flexible configurations to create dynamic surgical environments tailored to specific needs.

2. Understanding Modular Design Principles

At the core of modular operating theaters lies the principle of modularity, which entails dividing the surgical space into discrete, interchangeable units or modules. These modules encompass various elements, including walls, ceilings, flooring, lighting systems, HVAC (heating, ventilation, and air conditioning), medical gas supply systems, and integrated technology interfaces. Each module is meticulously engineered to meet stringent regulatory standards, ensuring compliance with healthcare guidelines and patient safety protocols.

3. Key Features and Advantages

- Flexibility and Scalability: Modular operating theaters offer unparalleled flexibility, allowing healthcare facilities to customize and reconfigure the surgical environment according to evolving requirements. Whether expanding existing facilities, retrofitting outdated theaters, or establishing temporary surgical units, modular design facilitates seamless adaptation and scalability.

- Rapid Deployment: The prefabricated nature of modular components enables swift installation and deployment of operating theaters, significantly reducing construction timelines and minimizing disruption to hospital operations. This agility proves invaluable in emergency situations, disaster response efforts, or during periods of heightened demand for surgical services.

- Enhanced Infection Control: Infection prevention and control are paramount in surgical settings, and modular operating theaters incorporate advanced features to mitigate the risk of nosocomial infections. Seamless surfaces, antimicrobial materials, HEPA (high-efficiency particulate air) filtration systems, and positive pressure ventilation mechanisms contribute to maintaining a sterile surgical environment and safeguarding patient well-being.

- Technological Integration: Modular operating theaters seamlessly integrate state-of-the-art medical technologies, including advanced imaging systems, surgical robots, anesthesia delivery systems, and audiovisual communication tools. These integrated solutions optimize surgical workflows, facilitate real-time collaboration among surgical teams, and enhance precision and patient safety during complex procedures.

4. Case Studies and Real-World Applications

Numerous healthcare institutions worldwide have embraced modular operating theaters as a cornerstone of their surgical infrastructure. From major academic medical centers to remote healthcare facilities, the versatility and adaptability of modular design have revolutionized surgical practice across diverse settings. Case studies highlight the successful implementation of modular operating theaters in enhancing patient care, reducing surgical wait times, and improving operational efficiency.

5. Modular Operating Theatre Product Portfolio

5.1 Automatic Door

Designed with precision and tailored to meet the unique demands of surgical environments, Operating Theaters Automatic Doors offer a seamless blend of functionality, safety, and hygiene.

Here’s a closer look at the key features and benefits:

-

-

- Sterile Operation: Operating theaters demand utmost sterility to minimize the risk of infections. These automatic doors are engineered to eliminate the need for manual contact, reducing the potential for contamination and upholding stringent hygiene standards.

- Effortless Accessibility: Designed for swift and effortless access, these doors facilitate the seamless movement of medical personnel, equipment, and patients in and out of the operating theater. Their automatic operation ensures smooth transitions without disrupting the flow of surgical procedures.

- Accessibility and Inclusivity: With accessibility in mind, these doors cater to the needs of individuals with mobility challenges, ensuring equitable access for all. Their user-friendly operation accommodates diverse users, promoting inclusivity within the medical facility.

- Quiet Operation: Operating theaters demand a tranquil atmosphere conducive to focus and concentration during surgical procedures. Operating Theaters Automatic Doors operate quietly, minimizing noise disruptions and fostering a conducive working environment for medical professionals.

- Integrated Security Features: To safeguard the integrity of the operating theater, these doors can be seamlessly integrated with security systems, controlling access and limiting entry to authorized personnel only.

-

5.2 Operation Theatre Control Panel

The operating room control panel is a centralized and sophisticated system designed to streamline and manage various critical functions within the operating theater environment. Here’s an overview of its features and benefits:

-

- Comprehensive Control: The Operation Theatre Control Panel serves as the nerve center, offering comprehensive control over essential systems and equipment within the operating theater. From lighting and temperature regulation to audiovisual displays and medical gas supply, it provides seamless management of various functionalities essential for surgical procedures.

- User-Friendly Interface: Equipped with an intuitive and user-friendly interface, the control panel simplifies operation for medical staff, enabling quick and efficient adjustments during procedures. Clear displays, tactile controls, and ergonomic design enhance usability, even in high-pressure surgical scenarios.

- Integration Capabilities: The Operation Theatre Control Panel seamlessly integrates with other hospital systems and technologies, such as electronic medical records (EMRs), imaging devices, and communication systems. This integration facilitates data exchange, interoperability, and enhanced coordination among healthcare professionals, leading to improved efficiency and patient care.

- Real-time Monitoring and Alerts: With built-in monitoring capabilities, the control panel provides real-time feedback on vital parameters, equipment status, and environmental conditions within the operating theater. Automated alerts and notifications promptly alert staff to any deviations or anomalies, enabling timely interventions and ensuring patient safety.

- Remote Access and Monitoring: Advanced control panels may offer remote access and monitoring capabilities, allowing authorized personnel to oversee operations, troubleshoot issues, and make adjustments from off-site locations. This remote accessibility enhances operational flexibility, particularly in emergency situations or when specialized expertise is required.

5.3 Medical Pendant

medical pendant is a crucial fixture in medical environments such as operating rooms, intensive care units (ICUs), and examination rooms. It is designed to provide support for medical equipment, gas, electrical outlets, network connectivity, and other essential utilities needed during medical procedures or patient care. Suspended from the ceiling, medical pendants typically feature multiple arms or booms, each equipped with various attachments and services.

Here’s an introduction to the features and benefits of medical pendants

-

- Versatility: Medical pendants are versatile systems that can accommodate a wide range of medical equipment and accessories. They may include gas outlets for medical gases like oxygen, nitrous oxide, and compressed air, electrical outlets for powering medical devices, and data ports for connectivity.

- Space-saving Design: By suspending medical equipment and utilities overhead, pendants help save valuable floor space in medical facilities. This is particularly advantageous in crowded environments like operating rooms where space optimization is critical for efficient workflow.

- Flexibility and Mobility: Many medical pendants feature adjustable arms or booms that can be easily maneuvered into position as needed. This flexibility allows medical staff to position equipment precisely where required, optimizing accessibility and workflow during procedures.

- Enhanced Efficiency: With medical equipment and utilities conveniently located on pendants, medical staff can access essential tools and resources without the need for additional movement or clutter. This improves efficiency during medical procedures and patient care activities.

- Enhanced Infection Control: Medical pendants can contribute to infection control efforts by reducing the need for floor-mounted equipment, cables, and cords that can harbor pathogens. Their overhead placement minimizes contact with contaminated surfaces, facilitating easier cleaning and maintenance.

- Integration with Medical Systems: Many modern medical pendants are designed to integrate seamlessly with medical monitoring systems, electronic health records (EHRs), and other hospital infrastructure. This integration enables streamlined data management and facilitates communication among healthcare providers.

5.4 Power Ground Module

Operating Theater Power Ground Module (OTPGM) is a crucial component within healthcare facilities, specifically in operating theaters, where precise and reliable electrical power distribution is essential for the safe operation of medical equipment and procedures. The OTPGM serves as a centralized unit for managing power distribution, grounding, and surge protection within the operating theater environment.

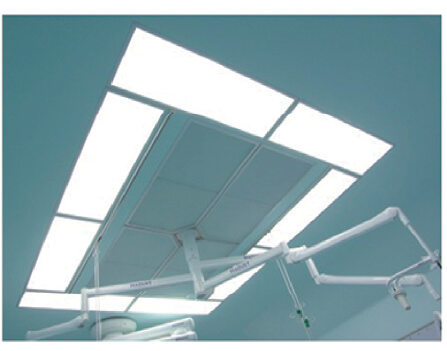

5.5 Laminair Air Flow

Operating Theater Laminar Air Flow systems are critical components of modern healthcare facilities, particularly in surgical environments. These systems provide a controlled and sterile airflow within operating theaters to minimize the risk of airborne contamination and maintain a clean environment conducive to surgical procedures.

5.6 Pass Box

Operating Theater Pass Box, also known simply as a Pass Box or Transfer Hatch, is a specialized piece of equipment commonly found in operating theaters and other sterile environments. It serves as a controlled transfer point for materials, supplies, and equipment between clean and contaminated areas, helping to maintain sterility and minimize the risk of contamination during surgical procedures.

5.7 LED X-RAY Viewer

Operating Theater LED X-ray Viewer, also known as an LED X-ray Illuminator or LED X-ray Lightbox, is a specialized piece of medical equipment used in healthcare facilities, particularly in operating theaters, radiology departments, and diagnostic imaging centers. It is designed to provide a uniform and high-intensity illumination of X-ray films, enabling healthcare professionals to view and interpret diagnostic images with clarity and precision.

5.8 Peripheral Lights

Operating Theater Peripheral Lights, also known as surgical lights or operating room lights, are essential fixtures in surgical environments that provide focused and adjustable illumination to assist surgeons and medical staff during procedures. These lights are strategically positioned around the operating table to ensure optimal visibility of the surgical field.

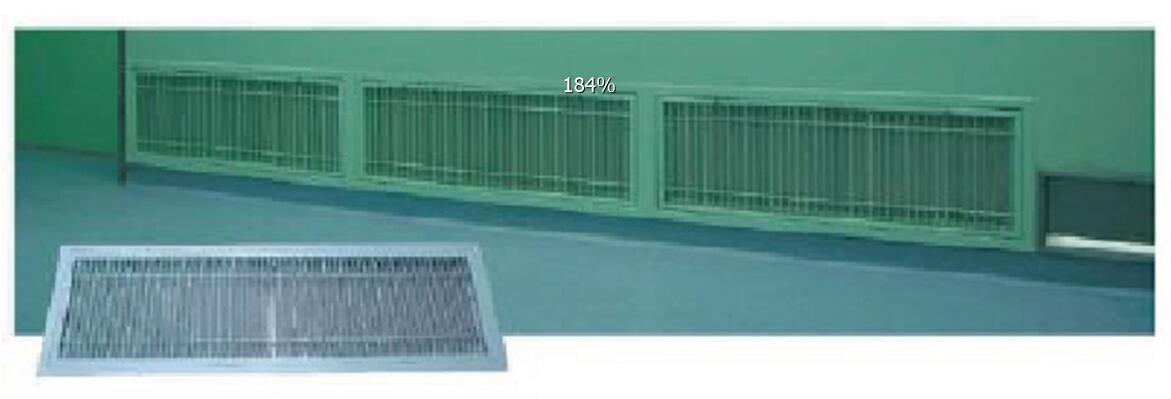

5.9 Return Air Grill

In an operating theater, maintaining a clean and sterile environment is crucial to prevent the spread of infections and ensure the safety of patients and medical staff. Operating Theater Return Air Grills play a vital role in this process by facilitating the controlled circulation of air within the operating theater.

Here are the key features and functions of these components:

Air Filtration: Operating Theater Return Air Grills are typically equipped with high-efficiency particulate air (HEPA) filters or other advanced filtration systems. These filters capture airborne contaminants, including dust, bacteria, and other particles, ensuring that recirculated air remains clean and free from potential sources of contamination.

Airflow Control: Return Air Grills help to regulate the flow of air within the operating theater, maintaining a balanced air pressure and ensuring proper ventilation. By controlling airflow patterns, these grills help to prevent the stagnation of air and minimize the risk of airborne contamination.

Sterile Environment Maintenance: Return Air Grills contribute to the maintenance of a sterile environment by continuously circulating clean air throughout the operating theater. This helps to dilute and remove airborne pathogens, reducing the risk of surgical site infections and other complications.

Positive Pressure Differential: In some cases, Operating Theater Return Air Grills may be designed to maintain a positive pressure differential between the operating theater and adjacent areas. This helps to prevent the ingress of contaminants from outside the theater, further enhancing sterility.

Quiet Operation: Return Air Grills are designed to operate quietly to minimize disruption during surgical procedures. The low-noise operation ensures a conducive and distraction-free environment for surgical teams.

Ease of Maintenance: Operating Theater Return Air Grills are designed for easy maintenance and cleaning to ensure optimal performance. Access panels and filters are typically easy to remove and replace, allowing for regular inspection and upkeep.

Compliance with Standards: Return Air Grills are designed and manufactured in compliance with relevant regulatory standards and guidelines for air quality and ventilation in healthcare facilities. They undergo testing to ensure that they meet stringent requirements for performance, reliability, and safety.

Overall, Operating Theater Return Air Grills play a critical role in maintaining a clean and sterile environment within the operating theater, contributing to the success of surgical procedures and the well-being of patients and medical staff.

5.10 Cabinets

Operating theater cabinets are specialized storage units designed for use in surgical environments to store and organize medical supplies, instruments, and equipment essential for surgical procedures. These cabinets are constructed with materials that meet strict hygiene standards and are tailored to the specific needs of operating theaters.

5.11 Scrub Station

Operating Theater Scrub Stations, also known as surgical scrub sinks or scrub stations, are specialized fixtures designed for hand hygiene in surgical environments. These stations provide healthcare personnel with a dedicated area to perform surgical hand scrubs, a critical step in infection prevention and control during surgical procedures

5.12 Medical Gas Socket Box

Operating Theater Medical Gas Socket Boxes, also known as medical gas terminal units or gas outlet stations, are critical components of healthcare facilities, particularly in operating theaters, intensive care units, and other clinical areas where medical gases are used. These units provide a safe and convenient means of delivering medical gases, such as oxygen, nitrous oxide, and compressed air, to medical devices and equipment.

6. Conclusion

The evolution of surgical environments epitomized by modular operating theaters represents a paradigm shift in healthcare delivery, blending innovation, efficiency, and patient-centric design. As the demand for surgical services continues to grow and healthcare systems confront unprecedented challenges, modular operating theaters stand poised to redefine the landscape of surgery, offering a blueprint for the future of patient-centered care. Through continual innovation and collaboration between healthcare professionals, engineers, and designers, the journey towards advancing surgical excellence and improving patient outcomes continues unabated.