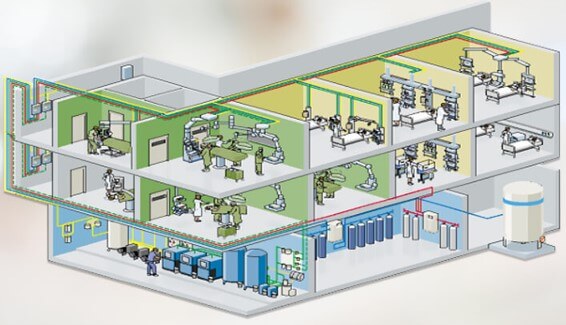

Medical Gas Piping System is a multi-professional and multi-disciplinary system engineering and is the only life support system.

In developed countries such as Europe and the United States, there are strict and detailed specifications for its design, manufacturing, and use, such as the US NFPA (National Fire Protection Association), the UK HTM (Health Technical Memorandum 2025), and international ISO standards.

Development history of medical gas standards:

- 1960s: Department of Health and Social Servies – the first medical gas guide ” HTM2022″

- 1980s: DHSS and the British Medical Gas Industry Association cooperated to develop the British Department of Health standard – C11 document

- 1990s: HTM2022 was revised to include the contents of the C11 document. Germany issued medical gas pipeline standards

1. Why do we need standards?

- When we think of standards, we always want to remember their advantages and disadvantages

- We need to know the reasons behind the regulations

- Ensure the basic safety and performance we need, as well as rational investment

2. Global medical gas standards

- HTM 2022 – United Kingdom ( HTM 02 issued in 2006 )

- NFPA 99 – United States, covers: Install, Equipment safety requirements, on-site inspection, run, maintenance

- ASSE6000 series, including: General Knowledge, Installers, Inspectors, Verifiers, Maintenance Personnel, Instructors, Designers

- HTM02-01, United Kingdom, includes: design, Install, Verification and Acceptance, Operation Management, Department Responsibilities, Operation management policy, Operation and maintenance process and work permit system, HTM AP02 Authorized Personnel (Operation), HTM CP02 Safety Inspector (Maintenance), Training, Cylinder Management, Safety, Maintenance management, Dental Air Systems, Dental Vacuum Systems

- ISO 7396-1 – General international standard covering: System equipment safety requirements, Install, Testing, debugging, certification, Operation Management

- GB50751-2012 – Technical Specification for Medical Gas Engineering

- AS 2896 – Australia

- NF S90-155 – France

- JIS T7101 – Japan

- SIS HB 370 – Sweden

- CAN/CSA-Z305.1-92 – Canada

3. Standard safety principles for medical gases

Regardless of the standard (norm), it is always for the same goal:

- Great patient care!

- First principles of medical gases:

- Always supply gas to the patient

- Second Principle of Medical Gases:

- Medical gases are medicines

4. Comparison of different standards

4.1 Should it be a two-stage or three-stage gas source?

| ISO 7396 | NFPA 99 | HTM 02-01 | GB 50751 |

| All gas sources are three (two for backup) | Two or three oxygen | Three or four oxygen sources (two as backup) | Three oxygen |

| Two medical air | Two or three medical air units with emergency backup cylinders | Two medical air | |

| Two medical vacuum | Three medical air conditioners (two as spares) | Medical equipment | |

| Only one gas tank is needed | Requires multiple gas tanks | At least one gas tank |

4.2 Is maintenance considered a “ normal” condition or a “single point failure”?

| ISO 7396 | NFPA 99/GB50751 | HTM 02-01 |

| Maintenance is a single point of failure – the system should be operating normally and fully redundant | Maintenance is not a malfunction – the system operates at a limited capacity during maintenance | Maintenance is a single point of failure – the system should be operating normally and fully redundant |

√ Normal Single point of failure

NFPA 99: √

EN/ISO 7396-1: √

HTM 02- 01 : √

AS 2896: √

CSA Z 7396 : √

GB50751: √

4.3 Medical air purity

| ISO 7396 | NFPA 99 | HTM 2022 | GB50751 |

| Any gas, any unit | Cleanest air outdoors | Use air from indoor ceiling height | cleanest air outdoors |

| Any compressor unit | Oil-free compressor units do not cause pollution | Any compressor unit (oil-free compressors are recommended) | Any compressor unit (oil-free compressors are recommended) |

| Cleaning treatment to meet pharmacopoeia requirements | Cleaning when required by testing (complying with pharmacopoeia regulations) | Cleaning according to pharmacopoeia regulations | Cleaning when required by testing (complying with pharmacopeia regulations) |

| Continuous monitoring of dew point | Continuously monitors carbon monoxide and dew point | Continuous monitoring of dew point | Continuously monitors carbon monoxide and dew point |

5. Air

5.1 How to make air “ medical”?

No Medical Air Piped → Any Compressor, Any Source → Oil Free Clean Source → Guaranteed Pharmacopeial Quality Air

In most places around the world, most of the time, outdoor air meets or exceeds the pharmacopoeia regulations for medical air.

Of course, sometimes this is not the case.

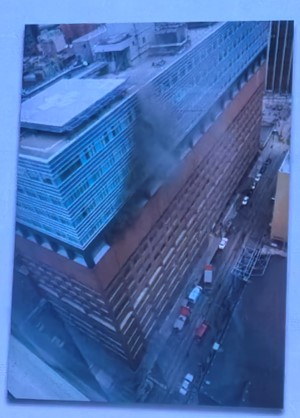

A fire broke out at St. Michael’s Hospital in Toronto. The small fire was quickly extinguished. Where is the medical air intake?

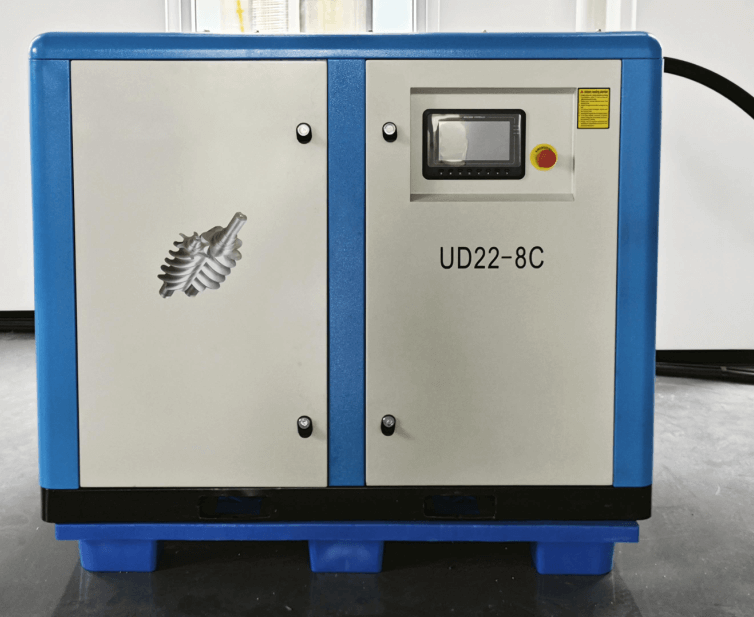

5.2 Compressor type

- Piston Reciprocating

- Scroll

- Oil Free Tooth

- Oil Free Screw

- Water injected Screw

- Lube Screw

- Lube Piston

The last two types of air compressors are not allowed by NFPA, but are allowed by ISO/HTM and are not recommended by GB.

5.3 Water in medical air

| ISO 7396 | NFPA 99 | HTM 02-01 |

| <67 ppm(v)

Pressure dew point ≤46°C The ambient temperature of all medical air ducts shall not be lower than -31°C |

Pressure dew point <0°C

All medical air duct ambient temperature should be greater than At 4°C Outdoor pipes must have anti-freeze protection measures Buried pipelines should reach the antifreeze depth |

<67 ppm(v)

Pressure dew point ≤46°C The ambient temperature of all medical air ducts shall not be lower than -31°C |

6. Medical vacuum

6.1 Requirements for vacuum pumps and gas tanks in different standards

| ISO 7356 | NFPA 99 | HTM 02-01 | GB50751 |

| Any type of vacuum pump | Any type of vacuum pump | Do not use water ring pumps | Water ring pump is not recommended |

| Requires bacterial filter | No bacterial filter required (required for 2018 version) | Requires bacterial filter | Recommended Bacteria Filter |

| Multiple gas tanks | At least one gas tank | Multiple gas tanks | At least one gas tank |

Now more and more countries require medical vacuums to be equipped with vacuum filters, considering the following:

- Protecting equipment maintenance personnel

- Eliminate any contamination that could flow back into the hospital and cause reputational damage

6.2 Vacuum flow

| ISO 7396 | NFPA 99/GB50751 | HTM 02-01 |

| 25 lpm | 85 lpm | 40 lpm |

| Minimum inner diameter of the tube: 20 mm |

7. Anesthetic waste gas emissions

Ideal anesthetic waste gas pump

- Operation: Drag the exhaust gas in the pipeline and pump it into the gas tank

- Fire prevention: No fuel in the system to create a fire hazard

- Low vacuum: Just enough vacuum, not too big

- High flow rate: ensures removal of waste gases

NFPA still allows five methods of venting waste anesthetic gases:

- Medical vacuum sharing (high vacuum sharing)

- Independent vacuum (independent high vacuum)

- Independent blower (independent vacuum)

- Jet type, driven by non-medical air

- Passive

| NFPA | EN737 WAGD |

| The flow rate is controlled by the doctor. | 25 lpm (0.9 scfm) @8cmH20″drag” |

| Typical flow rate is 6-9 lpm | 50 lpm (1.8 scfm)@ 4cmH20″drag” |

| Ignore vacuum pressure | Vacuum pressure is critical |

8. Air source location design

GB50751-2012: When the air inlet is located in the station, the medical air supply source shall not be located in the same room as the medical vacuum manifold, dental vacuum manifold, and anesthesia waste gas exhaust system. The compressor air inlet shall not be located near the motor fan or conveyor belt, and the indoor air quality shall be equal to or better than that of the outdoor air, and shall be able to be supplied continuously;

Explanation of the clause:

If the indoor air is treated to be equal to or better than the outdoor air quality requirements, such as filtered air from an operating room ventilation system, medical air intakes may be installed indoors as long as the air quality can be maintained continuously;

When the medical air supply source is placed in the same station room as the medical vacuum manifold, dental vacuum manifold and anesthesia waste gas exhaust system, if the vacuum pump exhaust port leaks or is under maintenance, the air intake of the medical air unit may be contaminated, so it should be avoided;

The use of a device to convert carbon monoxide into carbon dioxide in the medical air compressor unit, or the installation of an independent air filtration system, can be regarded as an improvement in the quality of the intake air. Under the premise of ensuring the quality of medical air, the requirements for the position of the air inlet can be appropriately relaxed.

9. Liquid oxygen storage

| Name of building or structure | Fire protection distance |

| Road inside the hospital | 3.0 |

| Walls or protruding parts of first- and second-level buildings | 10.0 |

| Walls or protruding parts of third- and fourth-level buildings | 15.0 |

| Hospital substation | 12.0 |

| Independent garage, underground garage entrance and exit, drainage ditch | 15.0 |

| Public gathering places, life support areas | 15.0 |

| Coal-fired boiler room | 30.0 |

| General overhead power lines | ≥1.5 times the height of the pole |

Note: When the exterior wall of the building facing the liquid oxygen storage tank is a fire wall, the fire separation distance between the liquid oxygen storage tank and the walls or protruding parts of the first and second level buildings should not be less than 5.0m; the fire separation distance between the liquid oxygen storage tank and the walls or protruding parts of the third and fourth level buildings should not be less than 7.5m. (GB50751-2012)

10. Valves (NFPA/GB)

The purposes of installing medical gas valves include:

- Zone valve fire protection

- Evacuate patients

- The valve is set near the ward, so there is time to evacuate the patient

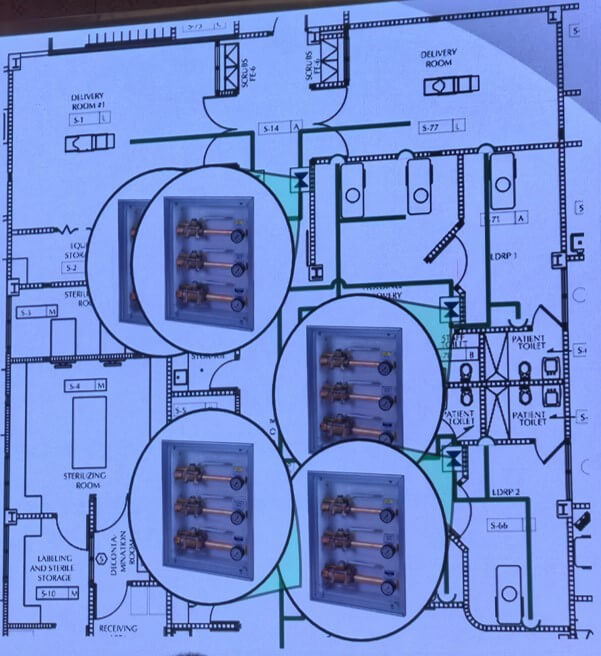

10.1 Zone valve setting requirements (NFPA/GB):

- Area valves must be installed on the same floor

- Each critical care or life support area must have its own zone valve.

- Zone valves must be located outside the room containing the gas terminals and must be separated by a wall.

- Zone valves must only control the outlet air on the same floor

- Each anesthesia area (including light anesthesia, deep anesthesia and general anesthesia) must be equipped with an independent area valve outside the room

10.2 Zone valve setting requirements (HTM):

- General ward – set up a zone valve near the ward entrance

- ICU, recovery room, infant special care and other areas – set up a zone valve at the entrance, and set up another zone valve to control 4 and 8 beds. The 8-bed zone valve shall not control more than half of the gas terminals in any department;

- Operating room – one zone valve at the entrance of each operating area (the operating area includes the operating room, anesthesia room and plaster room);

- Vacuum area valves should facilitate maintenance and isolation of designated departments;

- To avoid too many regional valves, some other departments (such as small operating rooms) with less than 10 terminals each should have at least one regional valve at the entrance of the department.

10.3 Zone valve box requirements

- NFPA requires the installation of a pressure gauge. One valve box can be equipped with multiple gas valves and multiple pipe diameters.

- NIST connectors must be installed on both sides of the HTM valve for emergency gas supply and purging during installation. One valve box for one gas, 2-3 pipe diameters

- ISO is similar to HTM, but allows multiple gases to be configured in one valve box

11. Area sensor

Alarm sensor regulations (NFPA/GB)

All sensors in the life support area should be located on the “patient” side of the zone valve

The sensor for the anesthesia area can be set on either side of the zone valve: if set on the patient side, each zone must have its own valve

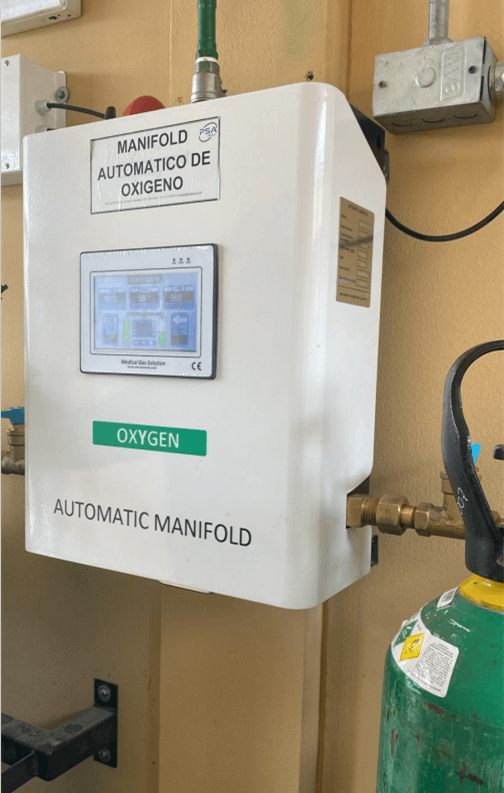

12. Medical gas manifold

- Equipment used directly in life support areas

- High reliability

- Fully automatic switching

- Prevent icing (CO2 and N2O)

- Gas supply during power outages

- Leakage (safety)

- Combustion-supporting gas, such as oxygen

- Toxic gases, such as nitrous oxide

- Asphyxiating gases, such as carbon dioxide, nitrogen, etc.

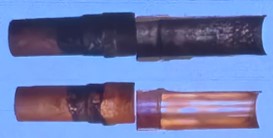

13. Pipe and welding

| ISO 7396 | NFPA 99 | HTM 02-01 |

| ISO is the only standard that recommends the use of metals but does not specify the construction material. | Medical gas can only use copper tubes, vacuum can use stainless steel tubes | Only copper tubes are allowed |

| Brazing (7396 does not specify the welding method, please refer to other standards) | Brazing, inert gas protection required | Brazing, inert gas protection required |

| welding | Tungsten inert gas welding |  |

| Bushing link | ||

| Low temperature shrink fittings |

14. Pipeline products

Why copper pipes are recommended?

-

-

- Copper has antibacterial properties

- High temperature resistance

- Corrosion resistance

- Easy to weld, reliable welding joints, no leakage

-