Guided by the needs of patients, medical institutions continue to expand the scope of medical gases application, and new medical technologies have spawned new applications of medical gases. The safety, science and economy of medical gas engineering use have attracted increasing attention from the medical industry.

This article focuses on the key parts of the application process of medical gas engineering, focusing on the diversification of oxygen supply, vacuum suction supply, compressed air supply, medical gas supply in the operation department, medical gas supply pipeline, medical gas user terminal, medical gas operation management and monitoring etc.

-

Oxygen supply diversification, ease of operation and compliance with regulations are the key

Oxygen is one of the main types of medical gases. Now hospitals mainly obtain oxygen sources through five ways: electronic means, pressure swing adsorption (molecular sieve oxygen production), low temperature method (liquefied air separation equipment), chemical preparations and membrane permeation oxygen production. .

Among them, in terms of energy consumption, the oxygen supply method of manifold is the most costly, because it is gasified by low-temperature oxygen and then produced by high pressure. The second is the oxygen supply method of liquid oxygen, the cost is 0.23 USD/m³, and the last is the oxygen supply method of the molecular sieve oxygen generator, the cost is 1.1~1.2 kWh/m³.

Relevant agencies have made clear regulations on the fire-fighting distance of medical liquid oxygen storage tank gas source stations and liquid oxygen storage tanks in medical and health institutions :

(1) The volume of a single tank should not exceed 5m³, and the total volume should not exceed 20m³;

(2) The distance between adjacent storage tanks should not be less than (3) times the diameter of the largest storage tank.

2. Vacuum suctionsupply avoidsviruses, and the area should be placed carefully

The pollution source of medical gas is mainly compressed air machine. With the development of technology, the application of vacuum suction makes the pollution source of medical gas no longer the compressed air machine.

There are four types of vacuum pumps: screw vacuum pump, water ring vacuum pump, rotary vane vacuum pump (dry type, oil type) and reciprocating vacuum pump.

The vacuum suction pumping station is a place where hospital waste liquid and waste gas are relatively concentrated. The waste liquid and waste gas basically come from patients in the hospital and may contain viruses. Therefore, the vacuum suction pumping station of the hospital should attract more attention. As a part of logistics, the vacuum suction pumping station of some hospitals is often set up together with other hospital stations, such as compressed air station, heat exchange station, liquid oxygen station, etc. Once a strong infectious disease breaks out, the vacuum suction pump station will become a potential source of infection. That is to say, the vacuum pumping station of the hospital should be located in a relatively independent area of the hospital.

In addition, during the treatment process, the vacuum suction system will inevitably have waste liquid immersion, which is mainly collected by the sewage collection tank in the ward and the central suction station. These waste liquids may carry bacteria and viruses. It should attract the attention of hospital administrators and designers.

The waste liquid should be collected in a centralized manner and sent to the hospital sewage treatment station for centralized treatment before being discharged into urban sewage. If it is inconvenient to be centrally treated by the sewage treatment station, it should also be treated locally in the station, and discharged to the urban sewage pipe network after reaching the urban sewage discharge standard.

Exhaust air should be led to the outside through pipes, and the exhaust outlet should not be in the flow area or densely populated area of the hospital. It is recommended that the exhaust outlet be located on the roof of the hospital building (this is especially true for vacuum suction stations located in the basement of the building).

Therefore, when the hospital configures the vacuum tank, it needs to ensure:

- It can ensure the stability of the vacuum suction system of the whole hospital;

- Reduce the number of start and stop of the vacuum pump and prolong the service life of the vacuum pump.

The size of the vacuum tank is generally not clearly specified in the specifications and standards. The larger the capacity of the vacuum tank, the more stable the system, and the increase in capacity requires a price (equipment cost + land occupation). Combined with years of experience in the industry, 1000 beds The volume of the hospital vacuum tank is generally 10m? is more appropriate.

-

There are many options for compressed air supply, and the criterionisto solve the demand

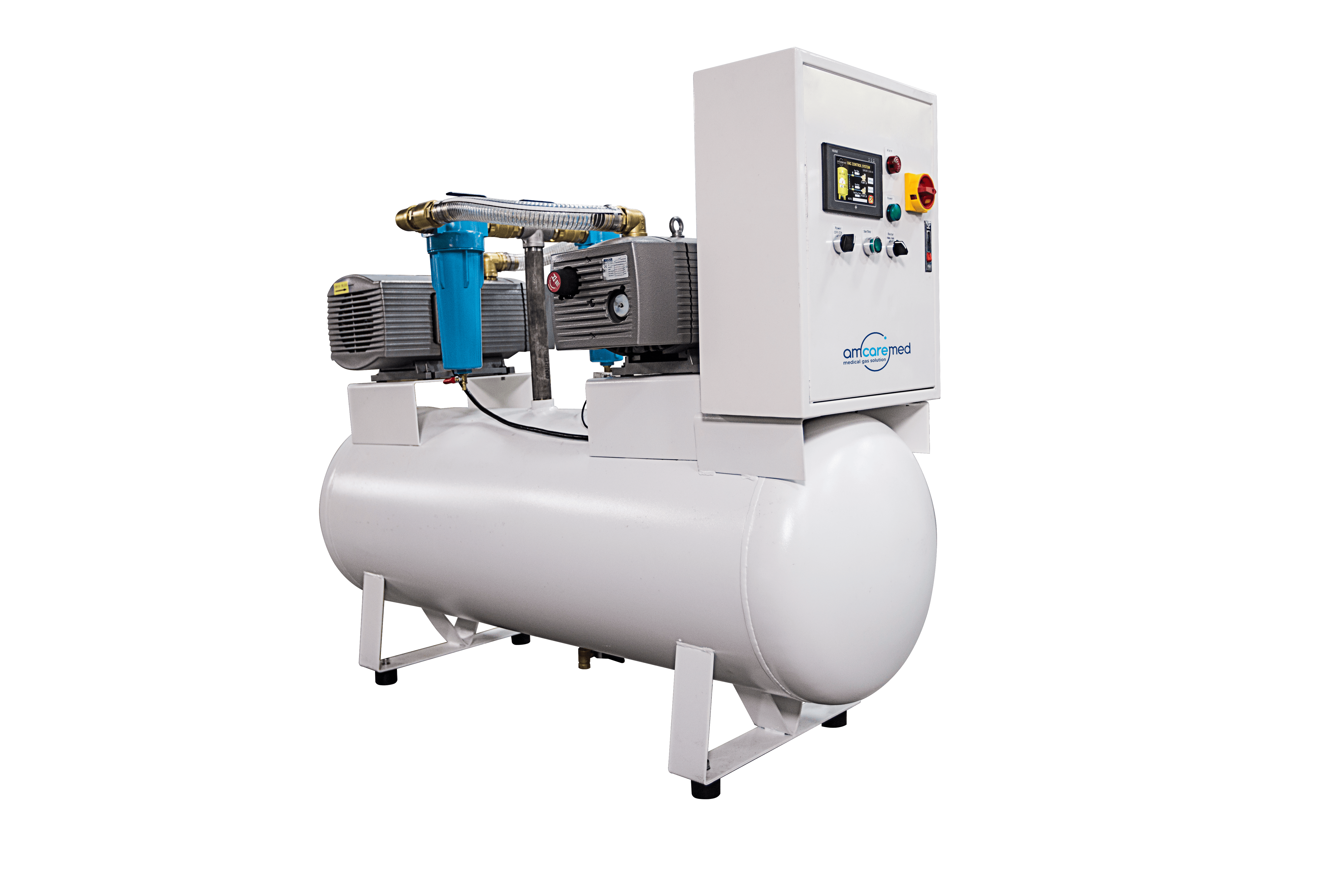

At present, there are more and more choices of air compressors, mainly piston air compressors, single-screw (worm) air compressors, centrifugal air compressors, twin-screw air compressors and sliding vane air compressors.

Among them, the sliding vane air compressor is a volumetric compressor. Compared with the piston air compressor, it has no suction, exhaust valve and crankshaft connecting rod structure. Direct connection, simple structure, easy manufacture, convenient operation and maintenance, and relatively cheap price.

In addition, since the vane air compressor is mainly a rotary volumetric compressor, it works relatively calmly, with little vibration and no complicated procedures. Because of the high speed and continuous air supply, the airflow pulse is small.

The application of compressed air in hospitals is often related to the treatment of patients, and there are certain requirements for the quality of compressed air. The air quality of the station room often determines the quality of compressed air. In order to ensure the quality of compressed air, the hospital should take corresponding measures:

(1) For the case where there are external windows in the station building, the compressor should take outdoor fresh air as much as possible, and the system without suction and exhaust pipes should pay attention to antifreeze in the northern region;

(2) If there is no external window in the station building, control the air supply and exhaust so that the air supply volume > exhaust air volume + air output of the compressor to ensure a slight positive pressure in the room. At the same time, ensure that the compressor is interlocked with the air supply and exhaust fans. Pay attention Start and stop sequence.

-

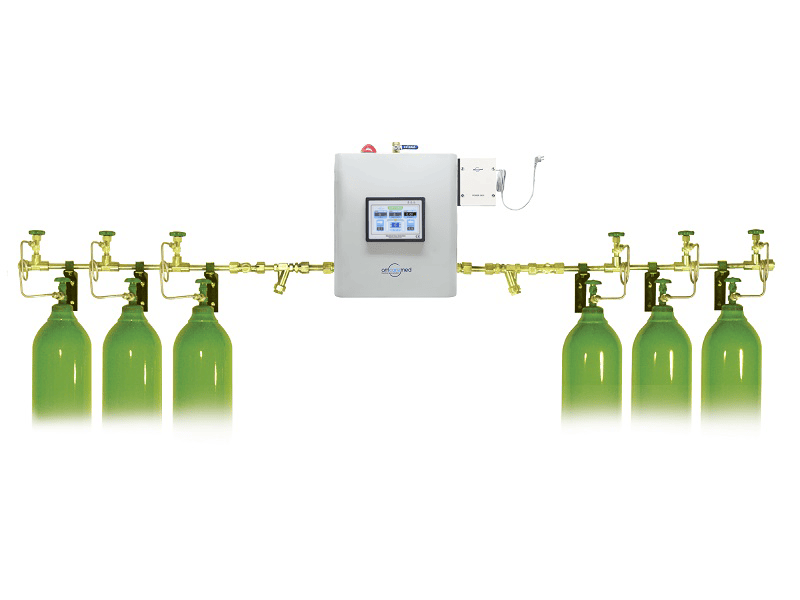

The medical gas supply requirements in the operation department are high, and the manifolddischarge should be differentiated

The types of medical gases in the operating department mainly include N2O, carbon dioxide, nitrogen, helium, and anesthesia waste gas collection and discharge, etc., and the supply methods are mainly manifolds or liquid tanks. For the medical gas in the operating department, it is now recommended to set the gas manifold in the operating department in or near the central operating department, and pay attention to the following two points:

(1) The device configuration is reasonable, and the workload of handling is reasonable;

(2) It is convenient for the operation department to manage this part and ensure oxygen supply.

In addition, regarding the collection and discharge of anesthesia waste in the operating department, there are currently two main methods:

(3) TheVenturi type device collects and discharges;

(4) Gas ring vacuum pump collects and discharges. The equipment of these two methods is relatively simple, easy to use, maintain, and change user adjustment, and at the same time, the vacuum control effect is better, and change user adjustment will generate energy consumption.

-

The medical gas supply pipeline is made of multiple materials, and safety is guaranteed in accordance with the specifications

Use seamless copper pipes, galvanized welded pipes for low-pressure fluid transportation, etc.

At the same time, the layout and installation of hospital medical pipelines must meet the following four requirements:

The work should be carried out in strict accordance with the relevant standards and specifications to ensure that the pipeline materials and installation quality meet medical needs, the pipeline must be clean, and the input pipeline must be degreased (standard).

The layout of pipelines should also be more flexible, especially oxygen pipelines. Oxygen is mainly a combustion-supporting gas. After pipeline leakage, oxygen accumulation and concentration increase will cause danger. Ventilation, which not only facilitates the pipeline layout of the hospital, but also ensures safety.

Vacuum suction pipes should not pass through the clean area of medical staff.

Medical gas pipelines must ensure safety and airtightness, and have the characteristics of anti-pressure, anti-freeze, anti-static, and anti-corrosion.

-

Safety use is the focus of medical gas user terminal settings

The principle of hospital medical gas terminal setting is mainly the following four points:

- Ensure safety, prevent wrong connection and damage;

- Reliable, ensuring quality, reliable dosage, and quantity meeting demand;

- The logo is obvious, which is convenient for patients and medical staff to use and operate;

- Aesthetic.

-

Medical gas operation management and monitoring, energy saving and environmental protection is the direction

Regarding medical gas operation management and monitoring, attention should be paid to oxygen supply classification, compression supply classification, vacuum suction, etc. Medical oxygen is divided into three types: treatment type, rehabilitation type and health care type. The hospital should adjust the supply concentration and guarantee the supply level according to the application of oxygen to ensure reasonable and economical use.

In terms of compression process classification, attention should be paid to medical air, especially the air condition of special equipment such as instrument air, laboratory, and dental chair air; vacuum situation.

All in all, in the process of operation management and monitoring of medical gas, patients’ needs should be targeted, gas terminal metering should be strengthened, refined gas management should be achieved, and gas supply adjustment based on patient signs should be realized.

Hospitals should face up to management costs and seek benefits from management, mainly strengthening management from the following three aspects:

- Energy saving for medical gas, various gas pipeline design, materials and construction techniques, and pipeline leak detection standards need to be improved to ensure that the leakage rate is minimized to achieve the goal of saving energy and saving fixed costs (electricity, water, gas, etc.) cost).

- The export terminals of various medical gases are preferentially selected from durable and airtight products to prevent waste of gas leakage caused by poor product design or poor quality and short service life.

- Strengthen the pressure alarm signals of various gases, and use various methods (wifi, etc.) to notify management and maintenance personnel.

At the same time, hospitals should integrate social resources, improve the level of medical gas supply operation management, and use Internet of Things technology to help hospital medical gas operation and maintenance management. Through the Internet, professional equipment manufacturers can find their own machines in the hospital and view various operating parameters and other information , To provide technical services for the hospital in time, so as to prepare early and not delay the normal use of hospital equipment.

In addition, energy-saving equipment and energy-saving technologies can be actively adopted, such as frequency conversion technology application, energy-saving product selection, etc., and through the construction of green hospital medical gas system, the impact of waste gas, waste liquid and noise on the hospital and surrounding environment can be controlled, so as to improve the hospital gas consumption. Improve operation and management level and strengthen gas monitoring.